AMAZON

SPHERES

Geometry of an Urban Oasis

Imagine strolling through an indoor garden filled with more than 40,000 plants, suspended rooms, and cantilevered walkways that provide the feeling of floating through the air. This paradise is just steps from one of the largest corporations in the center of Seattle, Washington. Known as the Amazon Spheres, three domed conservatories that bring nature to the city and provide respite to urban workers are a one-of-a-kind engineering marvel.

A kick-off meeting in 2013 with Amazon challenged the structural engineering team at Magnusson Klemencic Associates (MKA) and architectural firm NBBJ to design a landmark destination in Seattle. The team was asked to create a space reminiscent of a traditional conservatory offering an alternative workspace, providing employees a place to energize while temporarily “getting away from the city”.

Structural Engineering Innovation

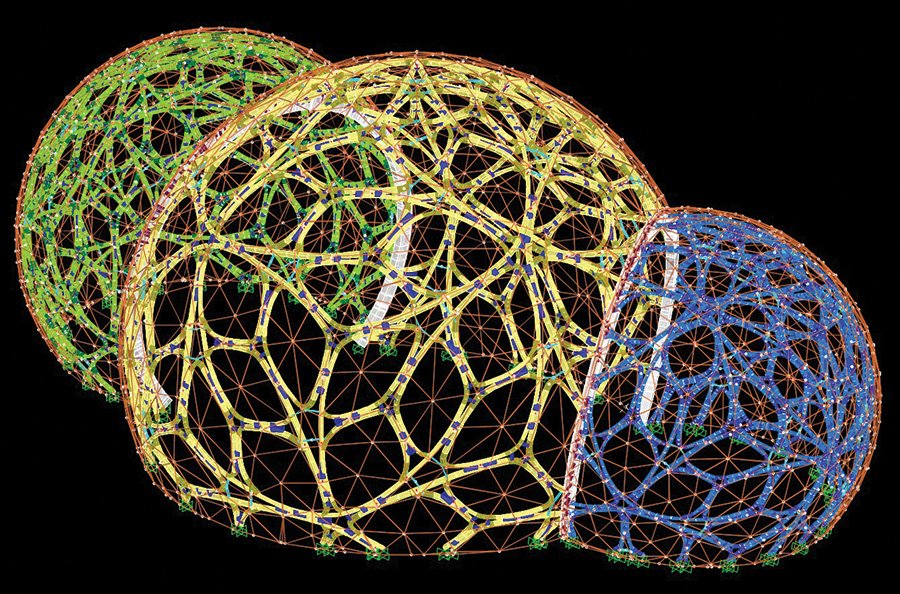

Inspiration for the design of the structures came from a spherical lampshade constructed by connecting a series of repetitive shapes. Structural engineers were inspired by this concept and worked closely with architects to develop a framing scheme for the Spheres that consisted of a series of identical interconnected pentagon-shaped steel segments that provided the unique, organic character central to the vision.

Structural engineers engaged with steel fabricators and detailers to draw from their experience and to better understand the boundaries of bending hollow steel sections (HSS). Armed with this knowledge, the team was able to develop geometries of the typical steel pentagon segments that were both structurally efficient and cost-effective to build.

Using specialized analysis software, the team of structural engineers built a virtual 3D model of the Spheres comprised of single pentagon segments linked together. The virtual spheres were then subjected to various loading scenarios, including seismic, wind and snow, and the steel HSS sections were optimized. Once completed, the analysis model included 16,000 individual steel elements and churned through 96 primary load cases in about 20 minutes.

Project Details

Managing Structural Engineer: Jay Taylor, Magnusson Klemencic Associates

Lead Architect: Dale Alberda, NBBJ

Completion Date: 2018

Materials: Structural steel

Tons of Steel: 620 tons

Erection Timeline: 6 weeks